TECH HIGHLIGHT: FUSELAGE RESISTANCE TO MATERIAL FATIGUE

Understand the forces at work on a fuselage and the best choice of materials.

As with all your equipment, your fuselage is a part that wears out with repeated loads. It has a long service life, but is not immune to material fatigue.

To understand what this means, it's important to know that a material can withstand heavy punctual loads, but the repetition of small loads can cause it to fail. This is a concept well known to engineers. For example, a 6 mm screw capable of supporting 1 tonne will eventually break if a 100 kg weight is suspended from it a million times.

An aluminum fuselage, for example, is perfectly capable of withstanding violent jumps when new, but in the event of very intensive use with repeated jumps, micro-cracks will gradually appear, eventually leading to failure on the final load, be it a small one. And it's not just jumps that put stress on your gear: the forces at work during a pumping or flat-start session with large front wings are considerable.

That's why we recommend replacing your Alu fuselage every year if you're a regular rider. Just like a board leash that needs to be replaced regularly, it’s a matter of safety first.

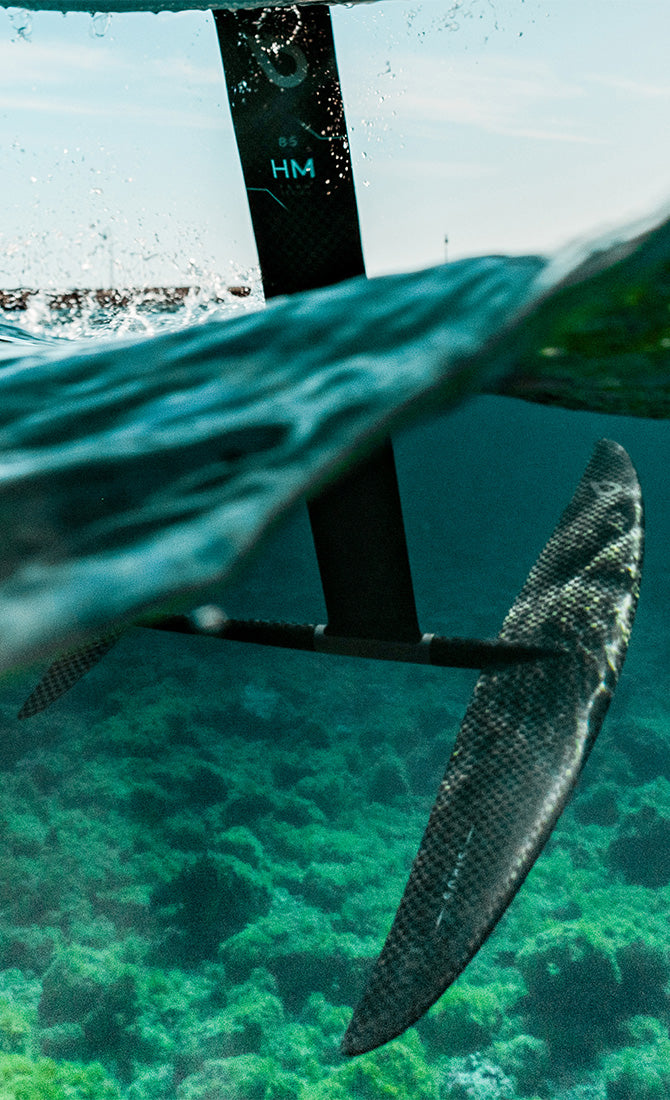

SUP Foiler: Malo, GONG team rider, with an Intruder EPS Pro, HM mast, titanium fuselage and Veloce HDW front wing.

What can be done to prevent material fatigue?

If you practice intensively and jump repeatedly, or with large wings when pumping, two solutions are recommended:

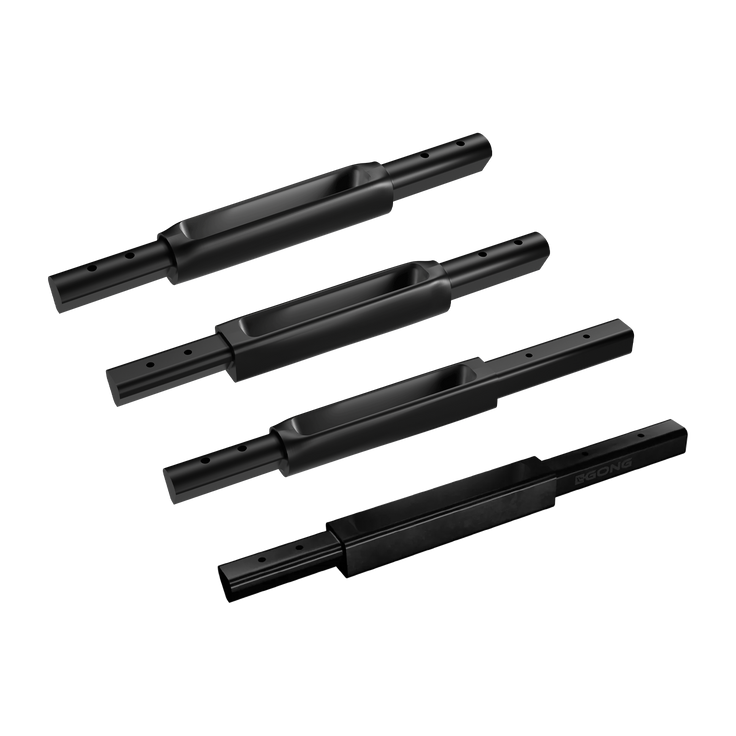

- Use a titanium fuselage, whose fatigue resistance is unrivalled. It’s also more resistant to corrosion in marine environments.

- Regularly replace your aluminum fuselage, which is to be considered as a wearing part. Every year for those who never miss a session. That's the reason why we offer it at the lowest possible price.

When using giant front wings (over 120cm wingspan), a titanium fuselage is necessary, as pumping is by definition a repeated effort, which will tire the fuselage more quickly than when simply flying, where your foil is subject to less stress.

Wingfoiler: Malo, GONG team rider, with a Stunt FSP Pro, Droid UPE Aramid X, HM85 mast, titanium V3 fuselage and Ypra Surf-Freestyle setup.

Using the Alu fuselage

This is the most widely used fuselage by our customers. We're talking about thousands of fuselages all over the watersports world, on which only a derisory amount of material fails due to mechanical fatigue have happened. The deformations or breakages we see occur before fatal fatigue, generally as a result of violent contact with the water bottom. But as the year passes and the load cycles are repeated, inspect your fuselage regularly, and replace it as soon as you have any doubts about its condition.

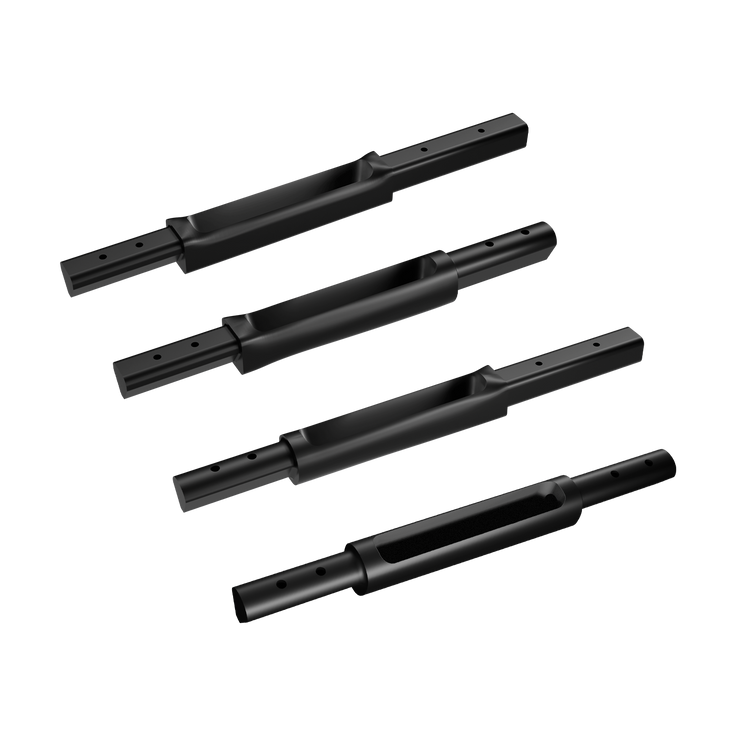

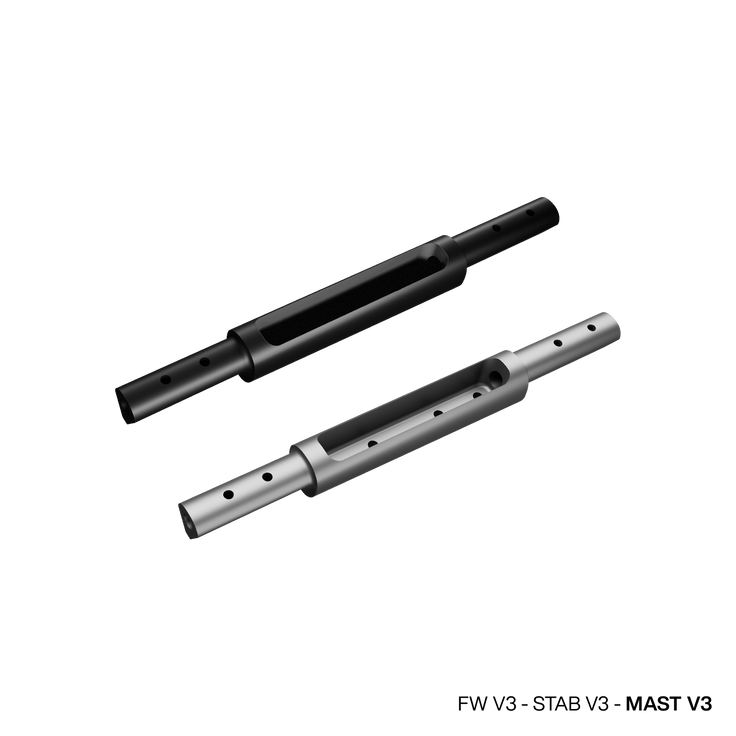

Structurally, the thicker vertical section of the V3 fuselage increases the foil's strength and rigidity. A considerable work has been carried out on the fillets, resulting in a 15% gain at break.

A few tips for maintaining your Alu fuselage:

- Rinsing after each session: After each session at sea, rinse the fuselage with fresh water to remove salt, which can cause corrosion.

- Protection against corrosion: Apply a light coat of marine grease such as Tikal Tef-Gel to screws and joints once a month.

- Avoid shocks and impacts: Handle the fuselage with care, as aluminum, although quite resistant, can be deformed under heavy impacts.

- Proper storage: Store the fuselage in a dry, moisture-free place, ideally in a cover to protect it from scratches.

By following these practices, you'll optimize the longevity and performance of your aluminum fuselage.