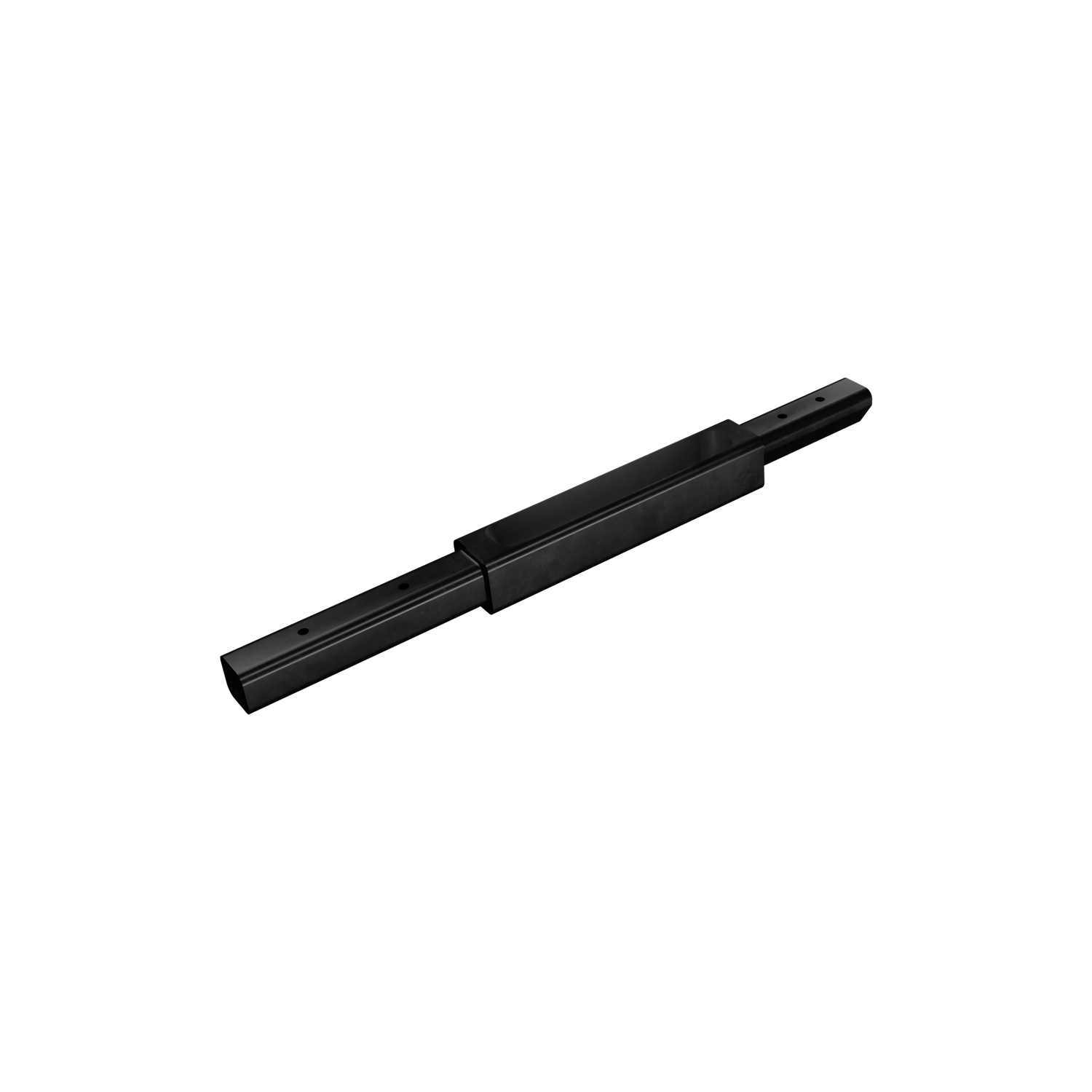

Pro Alu Fuselage Technology

This Pro fuselage is cut from high quality materials. The aluminium version is machined with a 3 axial CNC for maximum precision. The machine time is considerable. But starting from a block of metal makes it possible to use the best material to obtain a very resistant foil.

The aluminium technology offers the best strength/lightness ratio, at a nice price.

The fuselage is milled with a 3 axial CNC from a 6061 aluminium block of the highest quality for clockwork precision. The aluminium is then heat treated in T6 to provide outstanding durability.

Our R&D as well as our Quality Control guarantee you products of the highest quality. Firstly because our engineers based in South Brittany, France, are the first users. Their passion for our sports coupled with their qualifications have enabled us to create a unique research center in the world.

Our position as world leader in foiling is no coincidence. Our 3D simulations, our countless technical and technological prototyping, our state-of-the-art tools, our 100% GONG factory, our tests with the Pro Team which is among the most efficient, the thousands of feedback from our customers and our Ambassadors, and a ultra involved shaper designer: these are the key elements among many others that allow us to manufacture exceptional foils.

Several years ago, we were at the origin of the creation of the first foil factory in Asia, which today produces the “prestige” brands. 18 months of intense work and dozens of tools developed. Three years ago, we launched a new 100% GONG factory which allows us to produce more parts and keep our developments and technologies secret, to offer you the best of foils.

We want to offer low prices without ever cutting corners on quality, and refined products without ever diminishing performance in each program: we know what we are doing from A to Z. We do not sell foils designed by a freelancer, we do not do not sell marketing concepts. We do thorough, serious and innovative work to create efficient and solid foils at an unbeatable price.