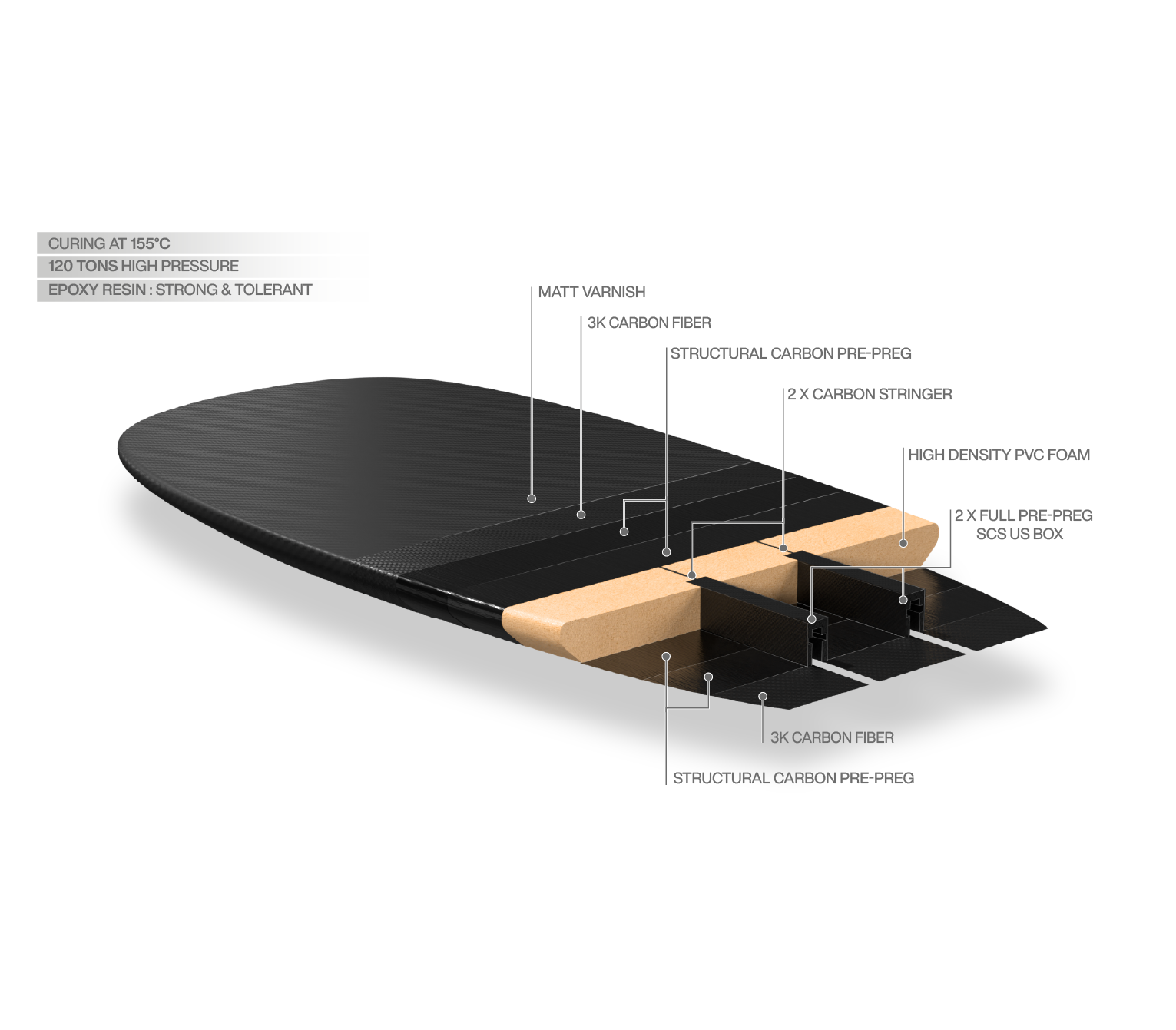

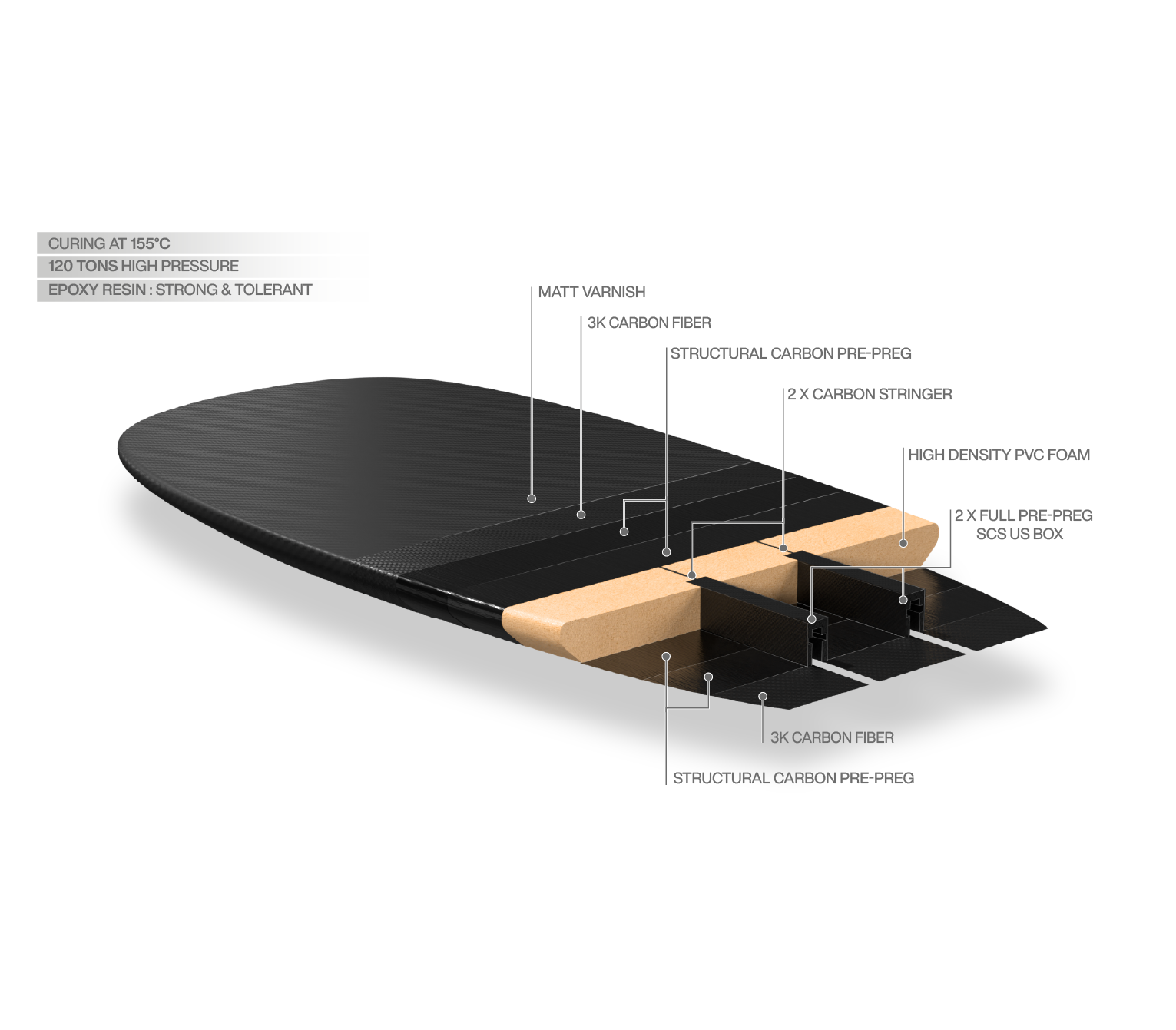

HDCC Technology

These boards have the high-performance HDCC (High Density Core & Carbon) technology. The manufacturing process is akin to that of a foil wing. The board is manufactured from aerospace-grade prepreg carbon fiber and a high-density foam core with mechanical properties that ensure structural cohesion and hydrophobicity in case of damage.

In a nutshell, it’s strong, stiff, and very lightweight

Industry-standard prepreg carbon fibers are positioned on the high-density foam core. Carbon H-stringers and full prepreg boxes are also placed before compression in a steel mold heated to 155°C to polymerize the resin. Mold pressure combined with high temperature ensures perfect layer cohesion to guarantee exemplary performance and durability.

Subsequently, the board is extracted from the mold. Board logos are applied. A thin layer of matte varnish is then applied to protect the board. The pad is glued, and the board is ready to ride!

This technology involves no sanding, hence no production waste. There's no sanding of the shape as it's molded, no sanding of the laminations which are pressed and fused, and no sanding of the hot coats which are integrated directly into the molding process. It's extremely costly to implement but the result is impeccably clean.

All our prototyping phases are tested on our own test benches. HDCC boards easily pass resistance tests with loads exceeding several hundred kilograms on the front foot.

The lower price compared to this exceptional technology is due to the efficiency of construction. Less human labor (about a quarter) equals lower expenses. Simply, with this board, you're primarily investing in well-assembled premium materials.

At GONG, our boards are top-of-the-line. Our competitive pricing is only possible due to direct sales, which eliminate intermediary markups. If, unfortunately, you break them, they are fully repairable with components we keep in stock for your favourite shape.