GEAR: HIGH-END TECH OF OUR INFLATABLE SUP BOARDS

At GONG our ambition is not only to offer a SUP board that is easy to transport and store, but also one that delivers solid performances on the water.

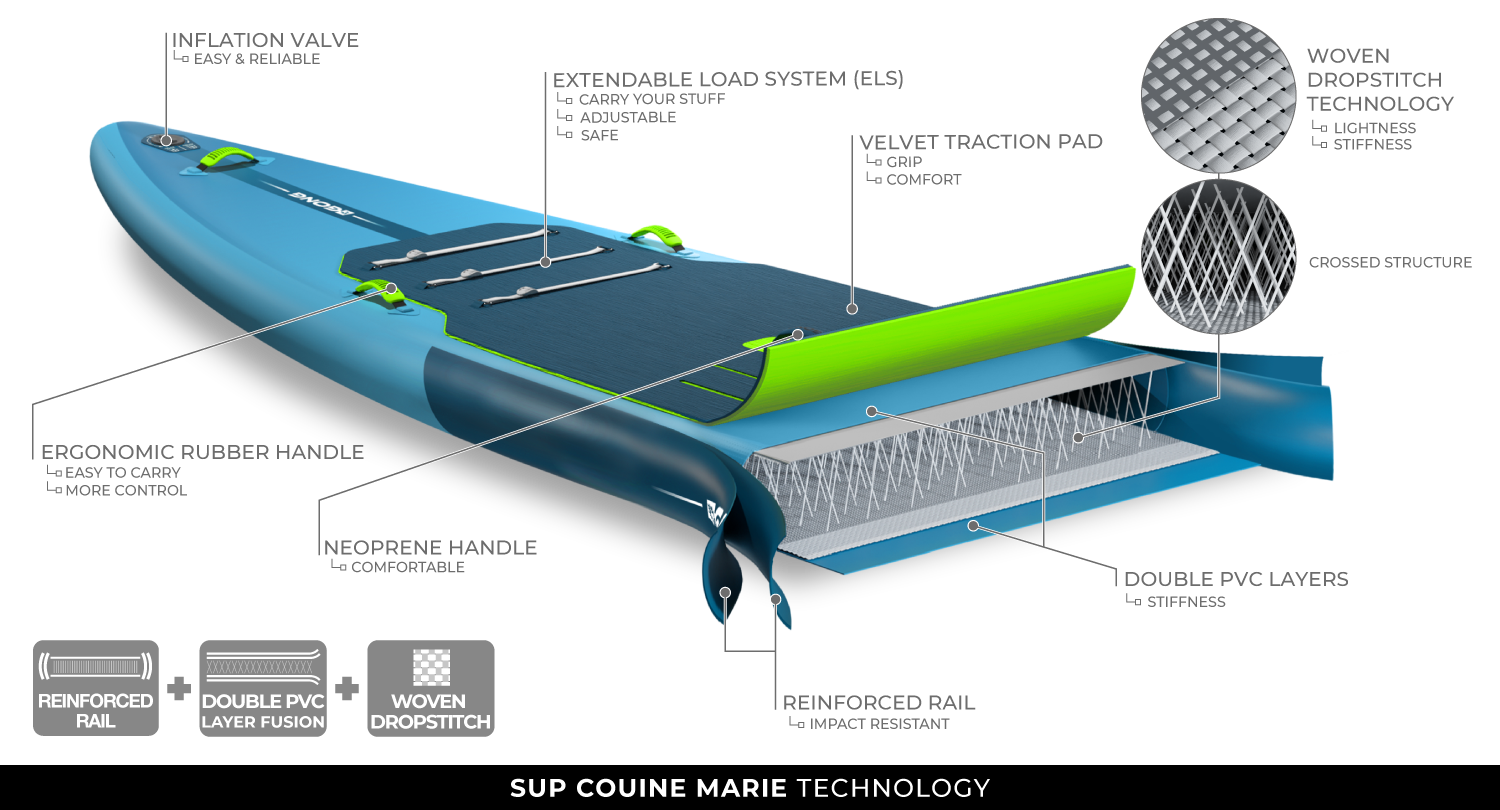

To achieve this, the technology used must guarantee flawless rigidity while maintaining minimum weight. In addition, at GONG we produce high-end boards which must be durable. This is therefore an ambitious triple objective which required a great deal of research and development.

- Weight savings of around 20% compared to the classic double layer (no glue between the 2 welded PVC layers).

- 30% stiffness gain compared to standard technology.

- Gain in strength: twice as resistant to drilling and abrasions as standard technology.

What is the Woven Dropstitch tech?

To understand Dropstitch, it is two skins that are connected by threads every x millimeters. These skins are made of waterproof PVC and the threads are ultra-resistant. All these threads are vertical and of the same length. They allow the two skins to be parallel under tension. When we create this mesh of threads, we are going to make “knots” on the surface a bit like canvas. Then we drown these surfaces in PVC to form the waterproof skins.

The particularities of the Woven is to be seen under two axes:

1/ Vertical:The Dropstitch threads are no longer aligned vertically but crossed at different angles, thus forming oblique struts that are cleverly distributed to balance each other. This concept gives much more rigidity to the whole.

2/ Horizontal:The flat braiding of the Dropstitch (the knots) becomes a very compact mesh which brings a great rigidity to the Board. In Woven Dropstitch the fibers are spread out instead of being in cylinders. This mesh is tighter and more homogeneous. It consumes less PVC in the interstices, like combed fibers which consume less resin in the Carbon.

The density of the mesh naturally increases rigidity and requires a thinner PVC backing than conventional Dropstitch (1.9mm vs. 2.5mm for equivalent rigidity). This optimized weave therefore allows the material to be considerably lighter, without altering its qualities.

Always Double Layer please!!

Attention, our tech remains a Double Layer thermo-welded with all its advantages of rigidity and strength.

What we call the Woven Dropstitch is the heart of the Inflatable Board, which makes the inner dynamics of the Board. But on the outside, nothing is better than a Double Welded Layer to protect your Board from aggressions.

For your information, the Woven can be offered in single or double layers. It’s obviously cheaper in a single layer 😉 Inform yourself and ask questions…