DON’T MISS OUT: AVAILABILITY ADVANCED BY ONE MONTH FOR THE KLUBER!

Good news for your dock start sessions with the imminent availability of the Kluber 80 and 95!

Initially announced for the end of May, the innovative Kluber will arrive a month early! Excellent news for pump foilers who have already placed their order, or for all those who are about to do so, since the Kluber 80 and 95 will be available from April 24!

To fly on the board whose rigidity, lightness and compactness allow you to fully exploit the qualities of your pumping set-up, go to our shop without delay! A board that fits in your foil bag for sessions with friends on the flat water spots near you.

Kluber 80 or 95?

The Kluber 80 is the benchmark for the pump foilers of all sizes. On the Kluber 95 you enjoy extra length to address any placement hesitations when going for your start. This length provides more ease in adjusting your stance when starting out, while offering a performance level analog to that of the Kluber 80.

How to choose? If the dock start is becoming easy for you, and getting the best out of your pumping setup is your goal, then the Kluber 80 is for you, regardless of your size. If you need to gain confidence, the Kluber 95 will be the magic carpet allowing you to push your setup to the limit.

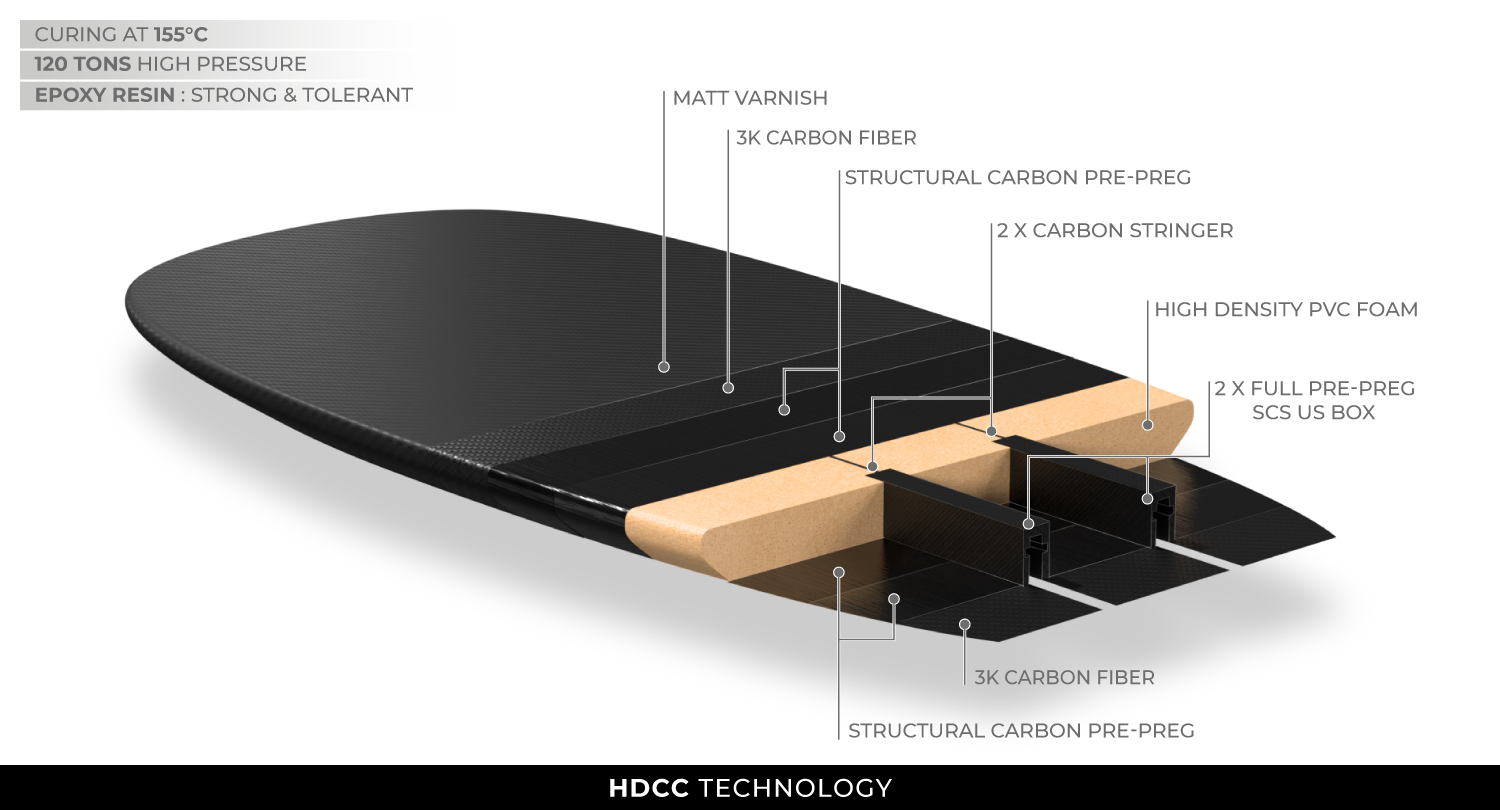

An unprecedented HDCC construction

Constructing a pumping board that is simultaneously comfortable, lightweight, rigid, robust, and durable poses a technological challenge due to the substantial forces at play when pumping giant front wings. Therefore, we are introducing an innovative construction for this board, drawing inspiration from what we do for our foils.

The HDCC construction (High-Density Core & Carbon) is a major advancement in pumping boards. With two carbon H-shaped stringers, a full carbon prepreg lamination, double-entry full prepreg SCS boxes, all pressed in a steel mold and baked at 155°C; this ultra-rigid construction maximizes performance and enhances your experience.

The high-density foam is hydrophobic. Zero stress in case of impact, especially since the rails are reinforced. Perfect for dock starting.

This technology involves no sanding, hence no production waste. No sanding of the shape since it is molded. No sanding of laminations as they are pressed and fused. No sanding of hot coats as they are directly integrated into the molding. It is extremely costly to implement, but the result is 100%.

A technology that drastically reduces production waste

This technology does not require any sanding of the shape since it is molded to the perfect shape in a single step. No sanding means no production waste. No sanding of hot coats either as they are directly integrated into the molding. It is extremely costly to implement, but the result is 99% clean.

1 comment

Hi. What is the soonest I can get a Kluber 80? Many thanks?