GEAR: GALVANIC CORROSION ON THE FOIL !!!

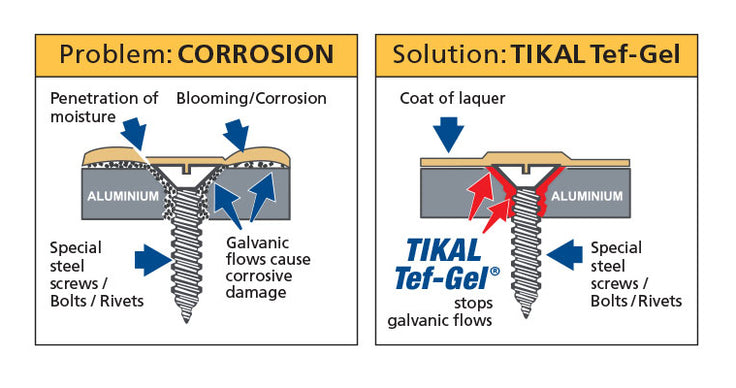

Most metals corrode when wet. Everyone knows this phenomenon from having witnessed it. Less is known about galvanic corrosion.

What is galvanic corrosion?

This is corrosion, the rate of which is increased by the physical contact of two metals. The speed of this reaction can be surprising. In just a few hours, a stainless steel screw can be literally welded to its aluminum thread. Disassembling your foil then becomes impossible. A screw welded by this phenomenon can break before even turning at all. It is therefore imperative to pay great attention to the maintenance of the elements of your foil.

Better safe than sorry

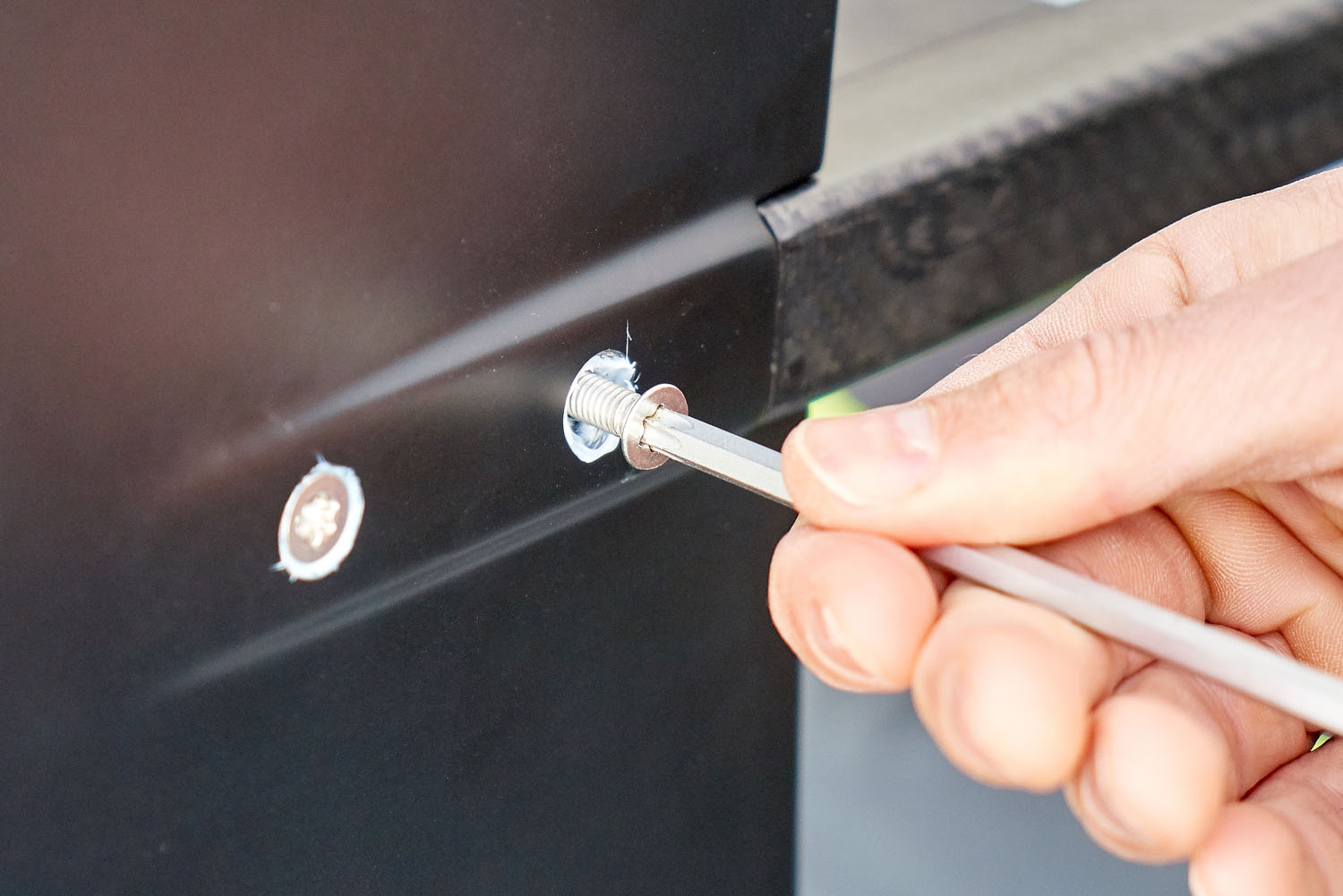

To prevent this phenomenon from happening, it is imperative to completely disassemble your foil after each session, to rinse and dry each part. We also strongly suggest using a specific anti-corrosion grease when assembling your foil. Thanks to this grease, direct physical contact will be cut between the different metals. It is therefore important to use a grease that is water resistant with a good hold. In our shop, Tikal Tef-Gel combines all these qualities.

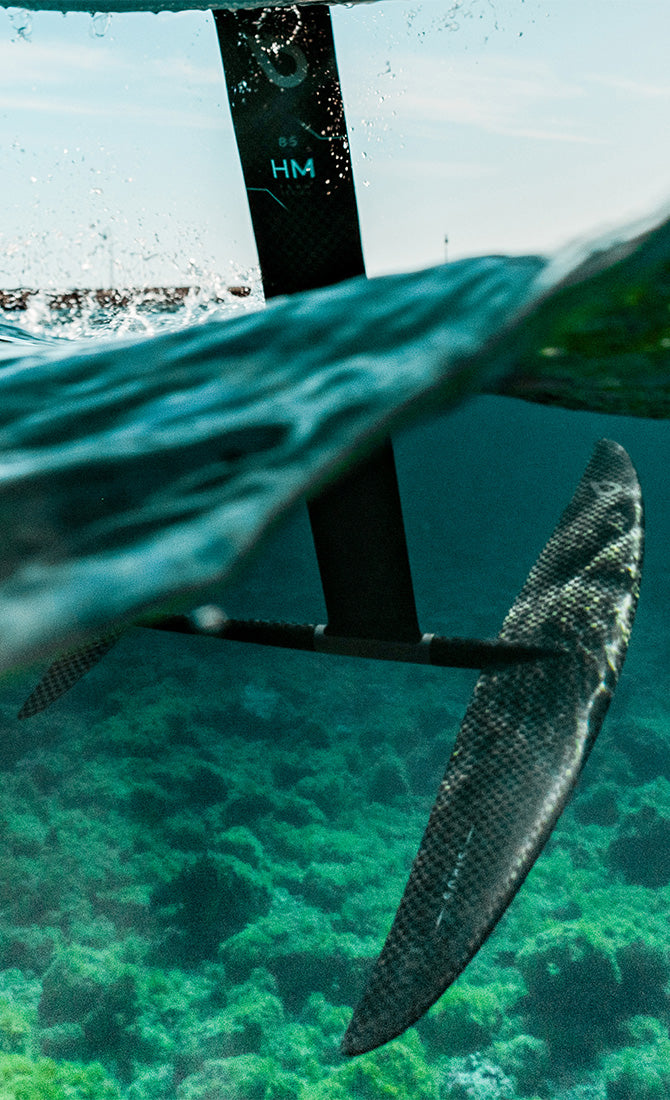

The case of carbon foil

Stainless steel is less prone to galvanic corrosion when combined with carbon fiber materials. However, this increases the risk of pitting and stress corrosion. A carbon foil therefore requires the same caution in relation to this phenomenon.