GEAR : about FSP technology !!!

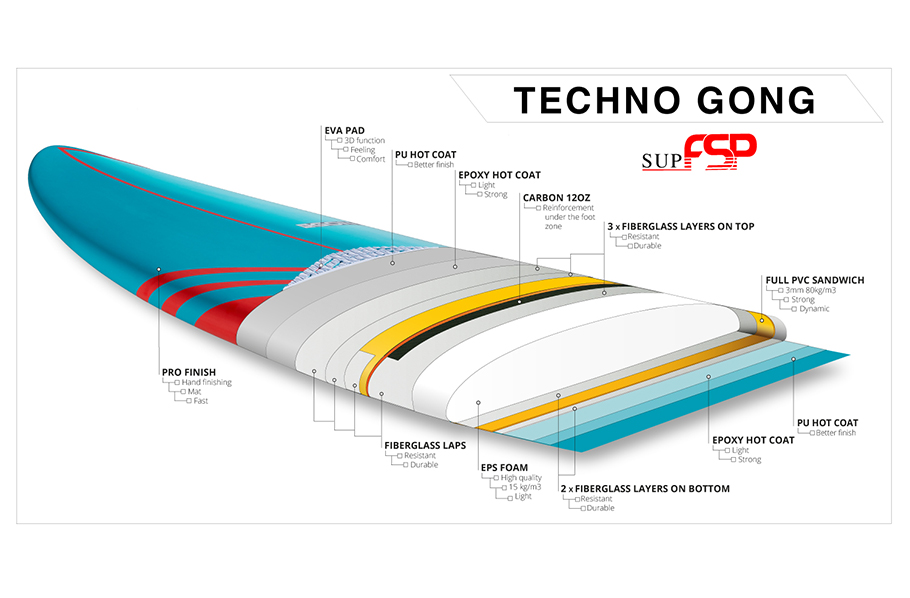

“It’s exactly one of the steps that takes up time on the FSP : the double shape.

I shape the perfect Board in 3D, then I re-shape it without the thickness of the PVC included.

Then it is reversed at the factory : we cut the shape without PVC then we glue it on in 2 vacuum stages.

After, we re-shape the Board by hand to give the PVC its final shape (which is the first one I did in 3D). And that’s where we get into the artisans aspect that is super long because the PVC material is hard like wood (80kg/m3). There is a lot of labor and seat that goes into getting those edges right. In fact it’s serious drudgery, lot’s of elbow grease and precision. And it’s all controlled by CNC templates taken from my 3D diagrams.

My backshapers really do some serious gruntwork.

It’s only after the steps are done that the ‘normal’ steps can be performed, like accessories and strats.”

Shaper : Patrice Guénolé et sa gamme GONG SUP FSP 2019.

Source : GONG SUP, the strong and light technology.

Source : GONG SUP, the strong and light technology.

Tags : GONG Surfboards, GONG SUP, SUP, stand up paddle, FSP SUP range, FSP technology, gongsupshop.com.