Fiber Glass Stab Technology

The wings, partly made of fiberglass, are thick to ensure easy takeoff. This thickness naturally makes them rigid, and the use of carbon fibers is not justified across the entire wing; we only apply them to critical areas, such as near the connections.

These wings have no flex. Fibers are oriented along multiple axes to lock in bending and torsion, ensuring maximum responsiveness.

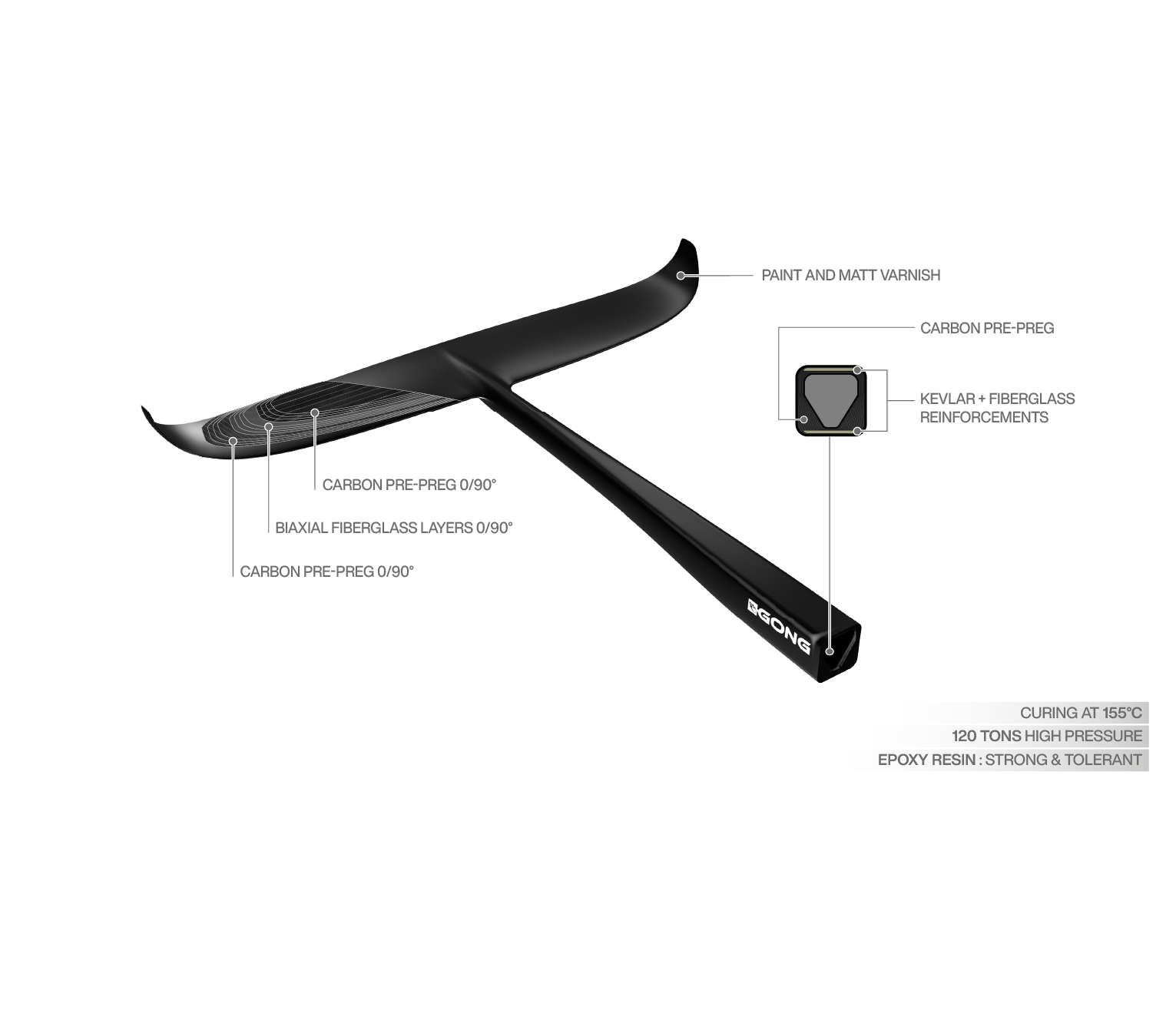

Thanks to pre-impregnated fibers, we can guarantee optimal resin usage, providing perfect cohesion at the lightest weight possible.

Each layer of pre-impregnated fiber is carefully hand-assembled around a high-density hydrophobic foam core, in a steel mold.

The mold is then subjected to high pressure and heated to 150°C to solidify the fibers. The foam core, seeking to expand under the heat, ensures even compression between the layers, guaranteeing a strong and durable structure.

Durability and repairability are at the heart of our development philosophy. Our foils are tested and proven by dozens of team riders, hundreds of employees, and thousands of customers worldwide. Even in case of damage, our products can be repaired multiple times, ensuring exceptional longevity.

Our Fiber Glass Stabs are mostly made of fiberglass with a few layers of carbon fiber. The choice of fiberglass is motivated by the thickness of the shape of the X-Over. Such a shape is naturally more rigid than the one of a thinner stab. You will not feel any flex on this wing. It is perfectly rigid.

The other advantage of fiberglass is that it is less afraid of shocks. We have a stab that will withstand the rough treatment a beginner will put it through.

It is also reinforced on the interlocking part because it is a point of strong tension on these powerful wings.

Finally, the advantage of fiberglass is that it is less expensive. This means a more accessible foil and therefore less hesitation before starting this fabulous sport. And the performances are there, do not doubt it. We don’t make you pay for very expensive carbon by claiming that it makes a difference. We use the perfect material for your needs!

This technology has been tested and proven for more than three years without any breakage on 60,000 ALLVATOR foil wings. In the event of a violent impact on a rock, you can easily repair them and they will be as good as new.

You will never see a GONG wing open on a leading edge because our unique draping technique crosses the layers of fibres. So there is no parting line on our wings. The entire outline has overlapping gaps, just like the rails on your top of the range boards.

This foil is completely dismountable to adapt to all sports at a lower cost and give you the possibility of replacing a damaged part. A complete spare parts catalogue is available, to allow you to make it compatible with multiple supports (Surf / SUP / Kite / Wing), and to explore the entire range of use of the foil in each sport and at all levels.

Please note that GONG is at the forefront of foil development. We have been at the origin of the creation of the biggest foil factory that produces the major brands today. 18 months of intense work and dozens of tools developed. So don’t imagine that our foils are made in a gloomy garage. We develop all our products according to the rules of the art, with many internal engineers, with state-of-the-art 3D software, countless tests, with a Team at the highest level. That’s one of the reasons why we can offer low prices and refined products: we know what we’re doing from A to Z. We do not sell freelance designed foils. Our teams are at work year round and dedicated to the development of our products.

Wing tips are a potential source of danger. We take care not to produce an intrinsically dangerous design, within the limits of efficient hydrodynamics. Likewise, the trailing edges are designed not to be dangerously sharp. We invite you to be extremely careful despite these precautions because these parts remain sharp and dangerous by nature. Stay away, wear the proper protections, and never sharpen them. Systematically repair the slightest hitch in the outline because it represents a danger for you and others if it were to cut your leash for example. In all situations, the greatest caution is required. If in doubt, abstain (waves, strong wind, etc.).

Our R&D as well as our Quality Control guarantee you products of the highest quality. Firstly because our engineers based in South Brittany, France, are the first users. Their passion for our sports coupled with their qualifications have enabled us to create a unique research center in the world.

Our position as world leader in foiling is no coincidence. Our 3D simulations, our countless technical and technological prototyping, our state-of-the-art tools, our 100% GONG factory, our tests with the Pro Team which is among the most efficient, the thousands of feedback from our customers and our Ambassadors, and a ultra involved shaper designer: these are the key elements among many others that allow us to manufacture exceptional foils.

Several years ago, we were at the origin of the creation of the first foil factory in Asia, which today produces the “prestige” brands. 18 months of intense work and dozens of tools developed. Three years ago, we launched a new 100% GONG factory which allows us to produce more parts and keep our developments and technologies secret, to offer you the best of foils.

We want to offer low prices without ever cutting corners on quality, and refined products without ever diminishing performance in each program: we know what we are doing from A to Z. We do not sell foils designed by a freelancer, we do not do not sell marketing concepts. We do thorough, serious and innovative work to create efficient and solid foils at an unbeatable price.